3 Pain Points Solved at the Loading Dock

The loading dock is essential to the operation of a business, but they add unintentional costs to an organization’s bottom line. Depending on the type of dock leveler, industrial doors or gaps created by other access points, elements are almost guaranteed to make their way into the facility. When outside elements seep into a facility the top three areas that are impacted include:

- Energy savings

- Ability to control temperatures

- Safety of team members

Let’s take a closer look at these three areas individually and then talk about possible solutions.

Energy Savings

This is most likely the one cost at the loading dock that, generally, goes unnoticed in a facility. Typically, a facility will focus on energy saving measures like lighting sensors, solar panels or HVAC; basically the “low-hanging fruit”. To further that point, a 2011 study done by Material Handling Industry of America pointed out that only 7% of the respondents identified the loading dock as having a key role in sustainability and energy waste. This means that a majority the respondents aren’t recognizing there’s at least one 8 ft. by 14 ft. opening that’s letting conditioned air get out of the building and outside elements get in. This large, blind spot can translate into an estimated annual energy cost of over $30,000 (based on ASHRAE guidelines for one 8 ft. by 14 ft. opening at 720 cycles per day).

Temperature Control

When storing perishable goods, keeping them at the proper temperature is essential to the safety of the product and ultimately the consumers who will use those products. Looking beyond energy savings, a loading dock with one 8 ft. by 14 ft. door (cycling 720 times in a day) is going to create an issue with spoilage. Due to the fact that at a minimum, every time the loading dock door cycles cold air is escaping. The problems from spoilage can vary from discoloration/order, bad taste, all the way to most dangerous pathogenic.

Pathogenic spoilage is caused by pathogenic bacteria, which has serious health consequences for consumers. According to foodsafety.gov, they consider the danger zone for pathogenic spoilage between 40 ⁰F (4.4 ⁰C) and 140 ⁰F (60 ⁰C). This is when these types of organisms can rapidly multiply, and these toxins will make consumers sick, even if they are cooked to a safe internal temperature.

Team Member Safety

On average, about 25% of all reported warehouse accidents happen at the loading dock. When you look at what type of injuries are occurring at the dock, a quarter of those (another 25%) are attributed to slip and falls*. Loading dock doors have the potential to let in elements, like rain and snow, that cause working areas to become slick. With the current pressure for team members at the docks to move, load and/or unload products as quickly as possible, it’s extremely important to ensure elements stay outside the facility.

Traditional Solutions

When a facility is looking to correct, or stay ahead of these loading dock issues they typically look to the below options.

- Installing an impact-able door that helps keep forklift damage to the dock doors at a minimum.

- Using compression seals on the doors to keep the weather seal out of harm’s way.

- Changing your dock levelers from traditional pit-mounted levelers to sealed dock levelers.

- Building a shelter around your dock doors that physically separates the dock from the rest of the warehouse.

Some of these options can be cost effective, impact-able doors for example, but building a dock shelter can become expensive and if warehouse space is being rented this may not be an option.

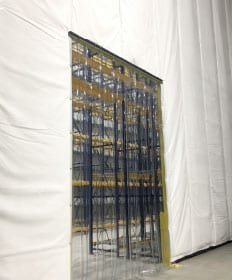

InsulWall®

Our insulated warehouse curtain wall (InsulWall®) can be used around the perimeter of internal and external loading dock areas as an excellent thermal barrier. Installed on roller track, InsulWall can be simply rolled back from the bay door and closed when the job is complete. Windows can be sewn within InsulWall to keep the dock area bright and safe. When compressors and heaters are working overtime to keep the dock area at a temperature set point, InsulWall can help conserve energy by not over-taxing equipment to keep up with the outside temperature.

Our insulated warehouse curtain wall (InsulWall®) can be used around the perimeter of internal and external loading dock areas as an excellent thermal barrier. Installed on roller track, InsulWall can be simply rolled back from the bay door and closed when the job is complete. Windows can be sewn within InsulWall to keep the dock area bright and safe. When compressors and heaters are working overtime to keep the dock area at a temperature set point, InsulWall can help conserve energy by not over-taxing equipment to keep up with the outside temperature.

Additional Benefits of InsulWall:

- More Economical – compared to permanent walls and metal structures

- More Environments – InsulWall is custom-engineered with a variety of R values

- Installs Easily – typically in a matter of days with little business downtime

InsulWall, from Randall Warehouse, is the modern solution for excellent temperature barrier between the outside and the dock area. Saving energy, protecting temperature sensitive inventory, and helping to keep the work environment safe are a few of the ways InsulWall is helping load docks meet the demands of today’s warehouse world.

*Note: statistics from Load Delivered blog in 2017.